IFP Manufactured Systems

IFP offers a variety of manufactured systems, system assembly, custom part manufacturing, and many other value add services to help reduce the labor, design, and engineering costs our customers incur when building their machinery.

Custom Products & Systems

Custom Hydraulic Power Units

Custom Hydraulic Power Units

Our power unit facility, located in our Ft Wayne Indiana headquarters, can design, build and test standard or custom hydraulic power units for a variety of applications. In addition we also design and build other custom products such as test stands and can provide and integrate a full controls package with our hydraulic units.

Custom Manifold Assemblies

Custom Manifold Assemblies

IFP engineers are trained to provide application assistance as well as circuit & custom manifold design. Our Ft Wayne facility is also fully equipped to build and test complete integrated circuits and IFP custom manifold products.

Custom Products & Systems

Custom Products & Systems

IFP manufacturing is done in our Ft Wayne Indiana headquarters. There we design, build, assemble and test various products and subassemblies for our customers. In addition we also integrate hydraulic products with the electronic technologies we offer and include non-hydraulic products in our assemblies.

Custom Hydraulic Suspension

Custom Hydraulic Suspension

IFP can help design custom OEM solutions for mobile and industrial applications, such as a custom suspension system for a field fertilizer tractor.

Custom Cooling Package

Custom Cooling Package

IFP can work with your company to offer a cooling package designed around your machine parameters

Integrated Electronic & Hydraulic Package

Integrated Electronic & Hydraulic Package

Integrated Electronic & Hydraulic Package

Hose and Tube Assemblies

Hose and Tube Assemblies

Hose and Tube Assemblies

Custom hose and tube assemblies, all major thread configurations and metric configurations available.

HyperPress Machines and Standalone Stations

HyperPress Machines and Standalone Stations

HyperPress Machines and Standalone Stations

Four standard designs from C-Frames, H-Frames, Equalizing Units and CGB small-form frames.

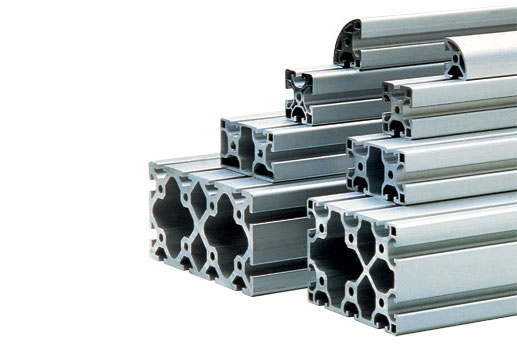

Extrusion Design

Extrusion Design

Extrusion Design

High-strength aluminum framing material of choice for assembling an unlimited variety of machine bases and frames, linear-slide systems, safety guarding, enclosures, worktables, material handling systems, and other industrial structures.

Extrusion Assembly

Extrusion Assembly

Extrusion Assembly

In addition to supplying a full product offering, IFP engineers can design a system for your needs and our technicians can kit all the parts you need for your particular application, allowing you to order one part number. We also can provide fully assembled product, simply with the aluminum framing assembled, or with other products also included.

Product & System Kitting

Product & System Kitting

Product & System Kitting

Kitting is a process of reducing manufacturing steps as a technique for cost and time savings.